It seems so long since I’ve posted anything for all of you. So I thought I’d write a little summary of what has been happening for me in the last year-and-a-half and hopefully get all of you caught up and set the stage for future posts.

Let’s see, where do I start?…

I guess at the beginning.

Many of you might know that I was working at NRI as a Digital Fabrication Specialist, almost single-handedly running the San Francisco satellite office for about a year-and-a-half after graduating with my Master of Science in Architecture from the University of Michigan, specializing in Digital Technologies.

For various reason, I left NRI about 18 months ago in April of 2015 and joined the San Francisco office of Perkins+Will, where I re-entered my profession of choice. Honestly, this is my dream job.

I began as an Arch 2 and was immediately put on a massive transit project in the Middle East. (Unfortunately I cannot share more yet but I will when I can. And if you happen to see it on google I can’t stop you.) I quickly gained invaluable experience in Revit (you truly do not know Revit or any other design software until you work on a real project with a team), as well as acquired a tease for transit work. The project quickly developed in a direction that gave me the opportunity to explore interoperability between Rhino and Revit. Little did I know that this would begin to mold the course of my time at PW and most-likely the rest of my carrier. Oh, and if all this wasn’t enough, I got married and became an insta-dad.

Amidst all of this, I also was given charge of the office’s model shop which I quickly re-branded as the Fab Lab—putting to use my experience at NRI to rethink how our office and eventually our firm approaches model making.

Since then I have have evolved into a computational designer, passed my LEED exams, become a champion of interoperability in the firm, joined the firm’s amazing Design Applications team as a Design Applications Tech, got involved in the firm’s amazing research department which we call the Process Lab, began volunteering on the committee of the San Francisco Dynamo User Group, and even had my first AU lab proposal accepted for AU 2016— not to mention the invaluable experience on more amazing projects than I can count.

While most of the projects I’ve been working on are either too early to share much detail or are still considered confidential by our clients, I can share a few snippets of some of my work and I will share more as I can in the future.

Of course the most important thing to me is my family:

My amazing wife and my beautiful daughter…

The PW SF Fab Lab (aka my play room)

Some of the things we’ve made in the Fab Lab…

I’ve got this incredible guy named Luc Deckinga as my boss. We are a dream team together and get to strategize together about office training, tool development, computational design and soooo much more. I could not ask for a better person to work with and work under.

My Boss…

In the office, we are constantly exploring and developing new tools to make our jobs easier, and newly designed products to improve our client’s quality of life while looking for ways to be more sustainable.

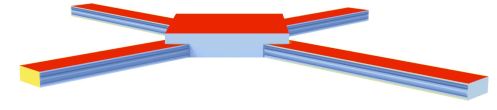

This is a skylight reflector system we’ve been prototyping in the office…

My research projects…

Some of you might have remembered posts of a deployable folding system from my time at Umich. Perkins+Will believe in innovation and encourages everyone in the firm to explore and try new things. They even provide mini-research grants twice a year. I was fortunate enough to be awarded one of those grants this past year and took my thesis project to the next level:

I have been involved in a number of computational design efforts, a few of which I can share below:

GFRC Optimization

This was an optimization I worked on to reduce the number of unique models required to manufacture the GFRC portion of project. The result was a reduction from 220 unique elements to 20 repeated types.

Facade Optimization

Exploring early facade design options and the potential impact on construction costs due to the number of unique panels. Further optimization was achieved by breaking the remaining unique panels into subsets for construction and fabrication rationalization.

Energy Analysis

I’ve had the fortune of being included on a number of energy analysis projects in conjunction with our Energy Lab for very large projects. It is one thing to analyze a building it is another to analyze a mega project like an entire airport or run hundreds, if not thousands of analysis options on a project at the same time. We are always pushing the boundaries and seeking to expand both our knowledge and capabilities as a firm.

Rhino2Revit

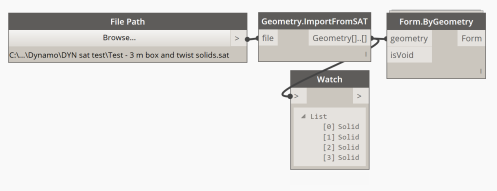

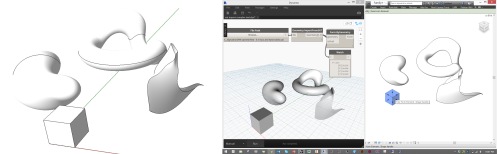

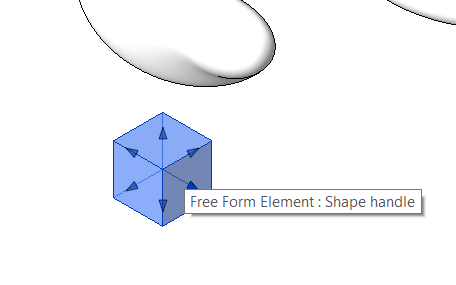

This Conceptual Design Revit Model for a small pedestrian bridge project was literally created in a day using Rhino, Revit and Dynamo. Later that week we had a full SD 100% set from Revit from the Rhino model…

This is one of the tools I’ve been developing on various projects to improve the way we design in our firm and hopefully our industry. I’ve had the chance of presenting it at the SF Dynamo User Group, will be sharing it at AU this year in November, and have posted about it in a previous blog post.

I’ve also had the opportunity to collaborate with some of the best minds in our firm and undoubtedly in our industry with the PW Process Lab….

Some of the things we’ve been working on:

- SpacePlanGenerator

- SFO Admin Campus

- Sprout Space Classroom

- and much more at DesignSpaceConstruction…

I’ve been extremely blessed in the past year—beyond belief. And I’m excited to see what’s to come…

Thought of the day:

When God gets us alone by affliction, heartbreak, or temptation, by disappointment, sickness, or by thwarted affection, by a broken friendship, or by a new friendship—when He gets us absolutely alone, and we are dumbfounded and cannot ask one question, then He begins to expound. . . .If you are going on with God, the only thing that is clear to you, and the only thing God intends to be clear, is the way He deals with your own soul. . . . There are whole tracts of stubbornness and ignorance to be revealed by the Holy Spirit in each one of us, and it can only be done when Jesus gets us alone. Are we alone with Him now, or are we taken up with little fussy notions, fussy comradeships in God’s service, fussy ideas about our bodies, Jesus can expound nothing until we get through all the noisy questions of the head and are alone with Him.

-Oswald Chambers

My favorite book next to the bible:

Have you ever been alone with God? January 13 My Utmost For His Highest

Check out the entire published works of Oswald Chambers online for free

Jude 1:1-7 bible study with Stan Josephsen on Words Of Righteousness Audio Library